Fairshare rules or supply allocation rules are defined for organizations for dividing the inventory based on a current demand ratio.

Functional Details

Navigation --> Service Supply Chain Planner --> Sourcing --> Supply Allocation Rules

Navigation --> Service Supply Chain Planner --> Sourcing --> Supply Allocation Rules

Important Fields

Name - Name of the supply allocation rule

Effective Date Block - Effective From/To Date of the rule

Organizations Block

Org - Organization to which the inventory is divided based on the Priority given in the priority field.Currently we have the fairsharing happening based on the current demand ratio.

Priority - Priority given to the org when dividing the inventory accroding to the current demand ratio.

Technical Details

Tables involved in creating the supply allocation rules are given below

Name of the supply allocation rules is stored in table - MSC_DRP_ALLOC_RULES

Organizations which are in fairsharing (Organization block ) are stored in table - MSC_DRP_ALLOC_RECEIPT_RULES

SQL Query

select rule_id,

name,

description,

planning_active,

plan_type

from msc_drp_alloc_rules;

select to_organization_id,

sr_instance_id,

receipt_rule_id,

dmd_priority, -- Demand Priority

rank -- Fairshare prority

from msc_drp_alloc_receipt_rules

where receipt_rule_id = 'rule id from above query'

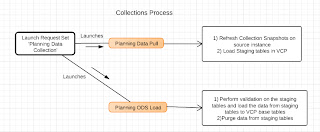

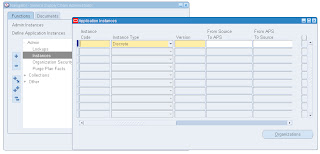

The above created supply allocation rules are setup in the assignment sets (for example at 'Instance/Org' level).

If the rule is setup at Org 'A' and the rule contains orgs 'B','C','D', and

If there is demand at org 'B','C','D', then the inventory at Org 'A' is divided into orgs 'B','C','D' based on the current demand ratio between orgs 'B','C','D'.